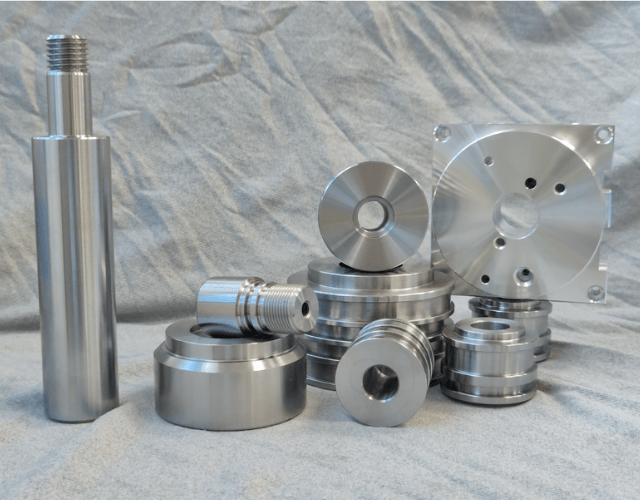

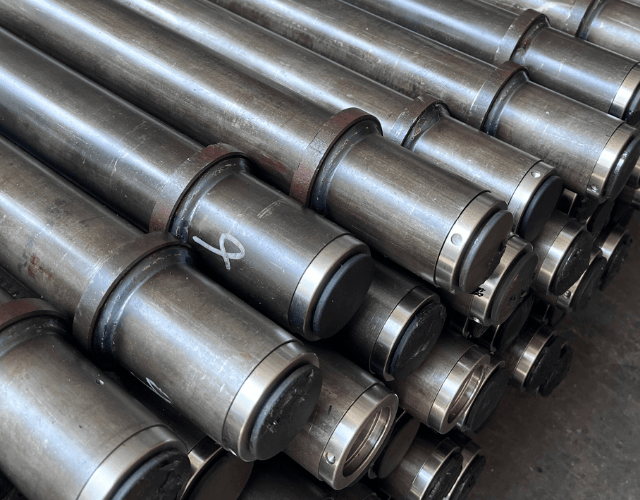

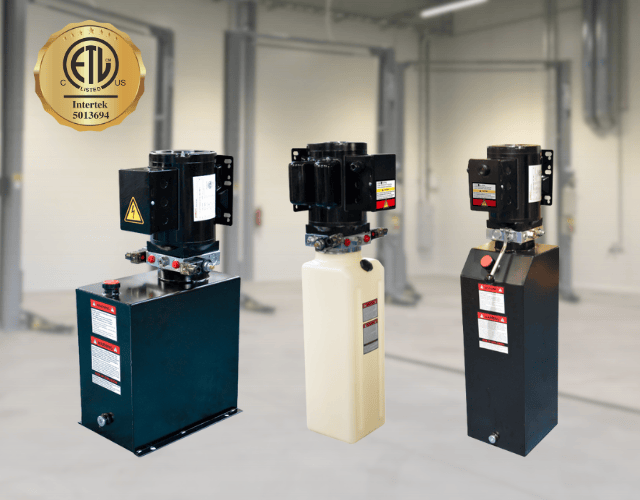

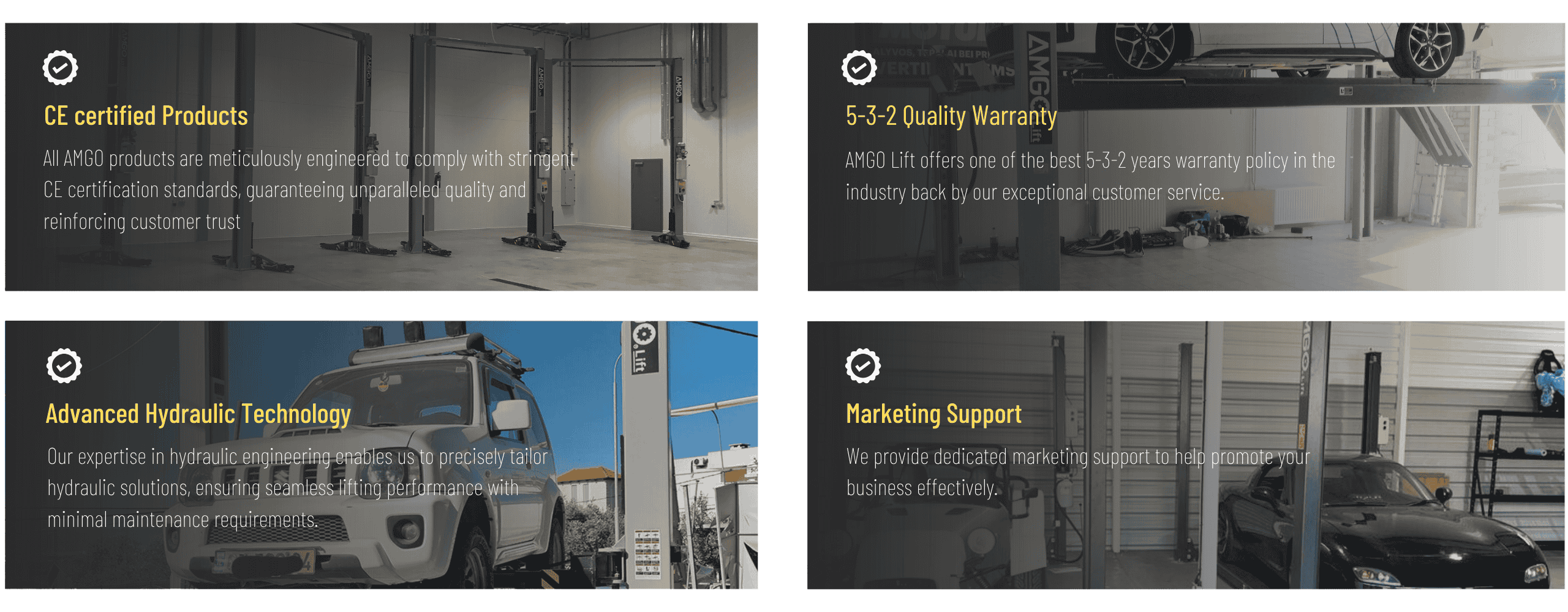

For decades, AMGO Lift has been at the forefront of hydraulic engineering, delivering precision-engineered lifting solutions for the global automotive industry. As one of the few fully integrated manufacturers in the sector, we control every stage of production—from advanced hydraulic components (motors, pumps, cylinders, and valves) to complete lift systems—ensuring uncompromising quality, reliability, and compliance with international standards. Our power units, rigorously tested and ETL-certified, exemplify our commitment to performance and safety, seamlessly integrating across our full range of CE-certified lifts.

AMGO Lift's portfolio is engineered to meet the most demanding industrial requirements, offering:

By prioritizing both innovation and market relevance, AMGO ensures that each product not only meets but exceeds contemporary industry standards, delivering unparalleled value to our clients.Through continuous innovation and rigorous exploration of advanced engineering solutions, we deliver proprietary features designed to enhance functionality, safety, and user experience.

Arm Lock Control Device

The Arm Lock Control Device, a nationally patented invention, is exclusively featured on AMGO's Single Post Series. Designed to enhance operational smoothness and guarantee absolute safety, this innovative system incorporates an integrated single-handle mechanism for effortless control of both arm locks. Simply pull and turn left or right to release the corresponding arm, with automatic re-engagement upon release for instant locking.

Double-Joints Bionic Arm

The innovative double-joints bionic arm comes standard with the SML-3000 and is also available as an optional kit for AMGO two post lifts. Its double-joints design enables flexible 180° movement and locking at any position, greatly enhancing the vehicle accessibility. Make the positioning more comfortable!

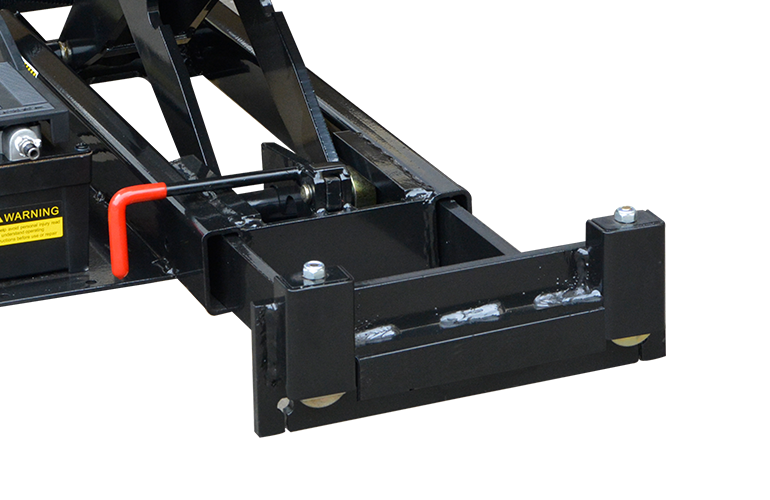

Float Rolling Technology

Starting in 2023, we implemented Float Rolling Technology across all AMGO rolling jack products. This advancement allows the jack to glide effortlessly on the rail when unloaded and stabilizes securely in the groove when lifting a vehicle, significantly enhancing performance efficiency and maintaining optimal jack condition.

Adhering rigorously to ISO 9001 standards, AMGO Lift operates under a Total Quality Management (TQM) framework, reinforced by 6S workplace discipline.

This systematic approach ensures operational excellence at every stage of production. Committed to precision manufacturing, AMGO lift integrates industry automation with expert craftsmanship to delivery superior product performance and durability. We has many advanced equipment such as Laser cutting machine, Mazak CNC machinery center, Robt welding system, and automatic assembly line etc.

Supported by a team of industry specialists and continuously evolving manufacturing capabilities, AMGO Lift remains at the forefront of innovation, delivering solutions trusted worldwide.

AMGO lift, the right equipment to lift your business.